Why is cold chain monitoring important?

The term “cold chain” refers to the kind of products in the supply chain, which are sensitive to temperature.

All organic products, such as fruit, vegetables, or any other type of food or live products, are sensitive to temperature. By need to protect the consumer, the government can force companies to comply with regulations such as HACCP. Securing the cold chain meets the requirements of the consumer, complies with government regulations and at the same time protects product performance and ultimately enhances profits.

But how do you identify temperature-sensitive chemicals which are exposed to critical values?

IntroTech can provice best practice solutions in the field of cost-effective & easy-to-use solutions to monitor the cold chain.

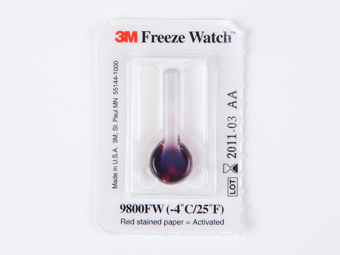

Monitor conditions with indicators

If products are sensitive to exposure outside a certain temperature range, the cold chain should be monitored to ensure the the product is safe.

IntroTech offers a range of indicators which make monitoring the cold chain in the food industry easy. Simply attach the label to the shipment. When a temperature excursion takes place the indicator will change colour.

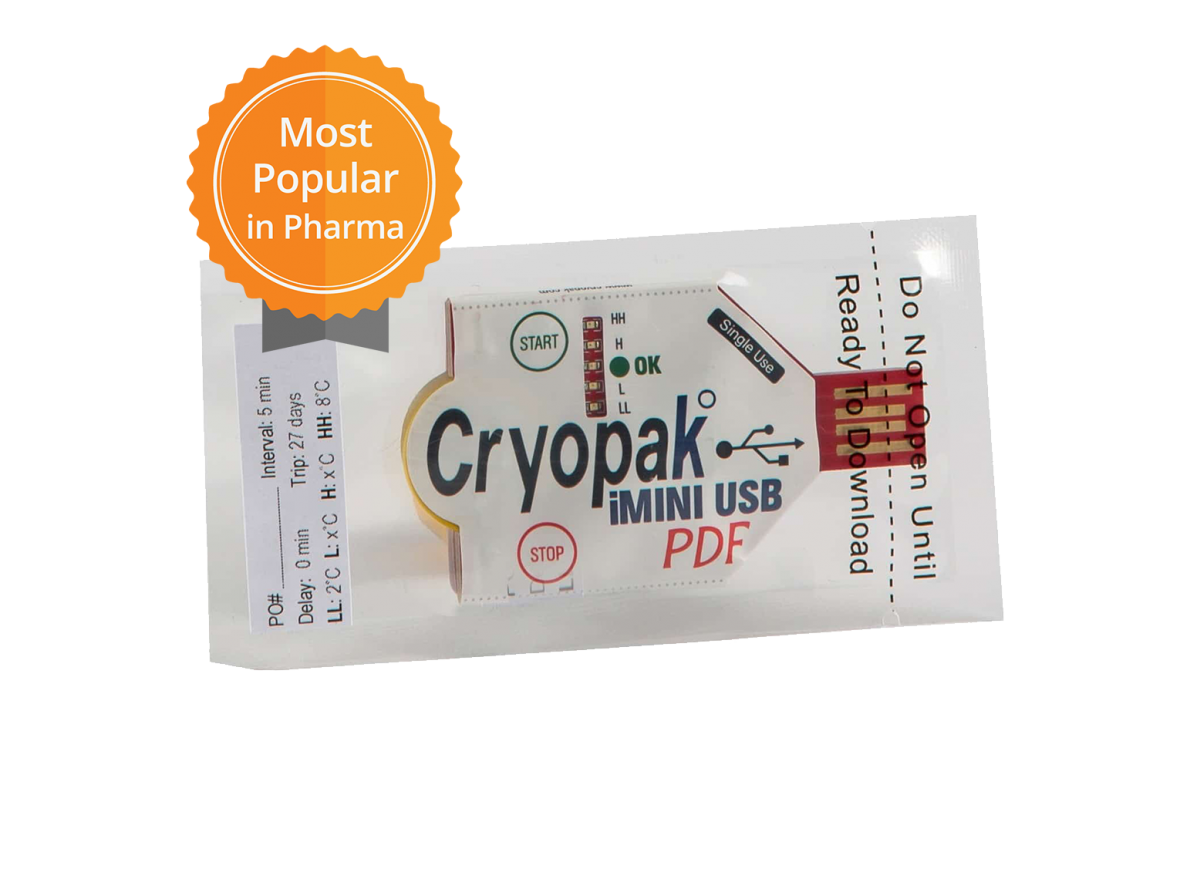

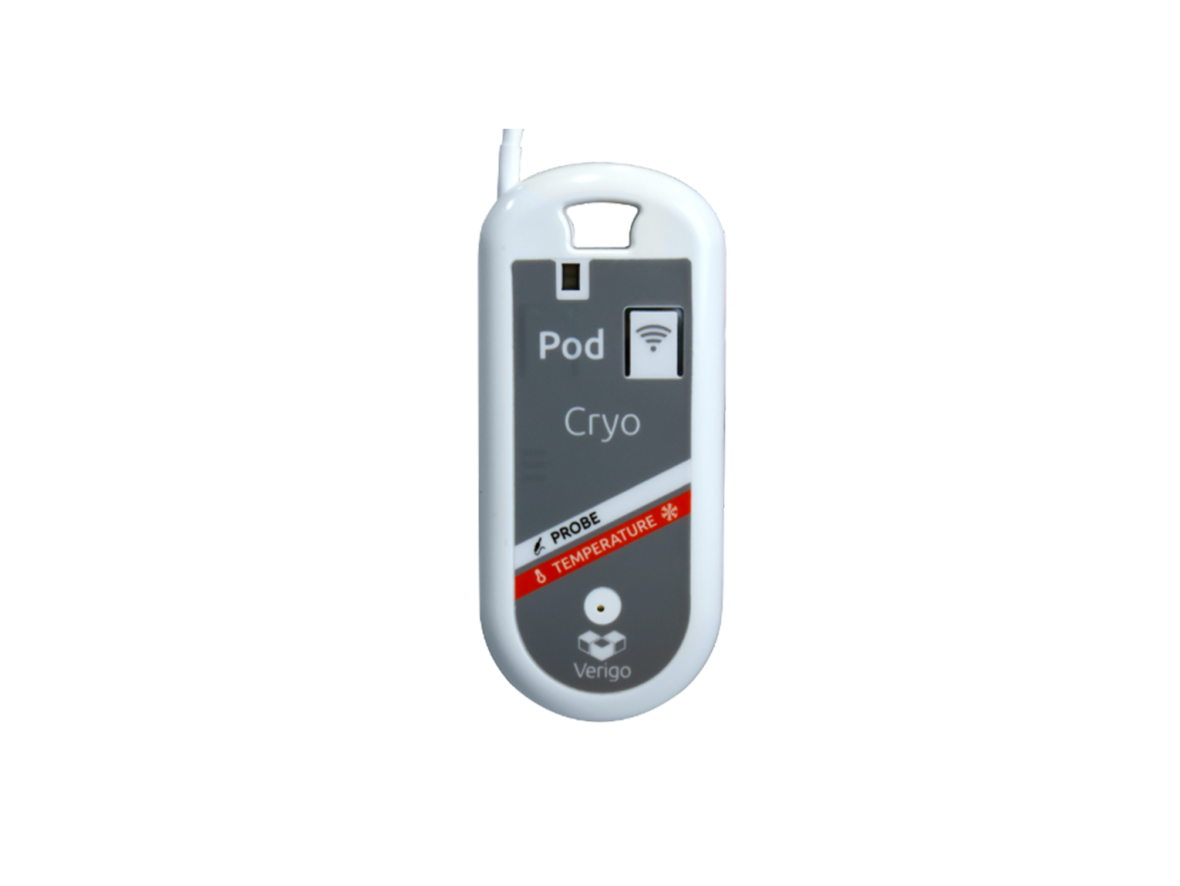

Record environmental data with dataloggers

In the cold chain of the food industry a record of the temperature values of a product is often mandatory. This data can be recorded with a datalogger. We offer dataloggers which collect and store data automatically.

USB PDF loggers generate output in PDF which can be accessed via USB, simply plug-and-play. Verigo dataloggers use bluetooth to connect with a mobile device. Once connected, conditions can be monitored in real time. The logger outputs data to a cloud-platform from which data analysis can be performed.

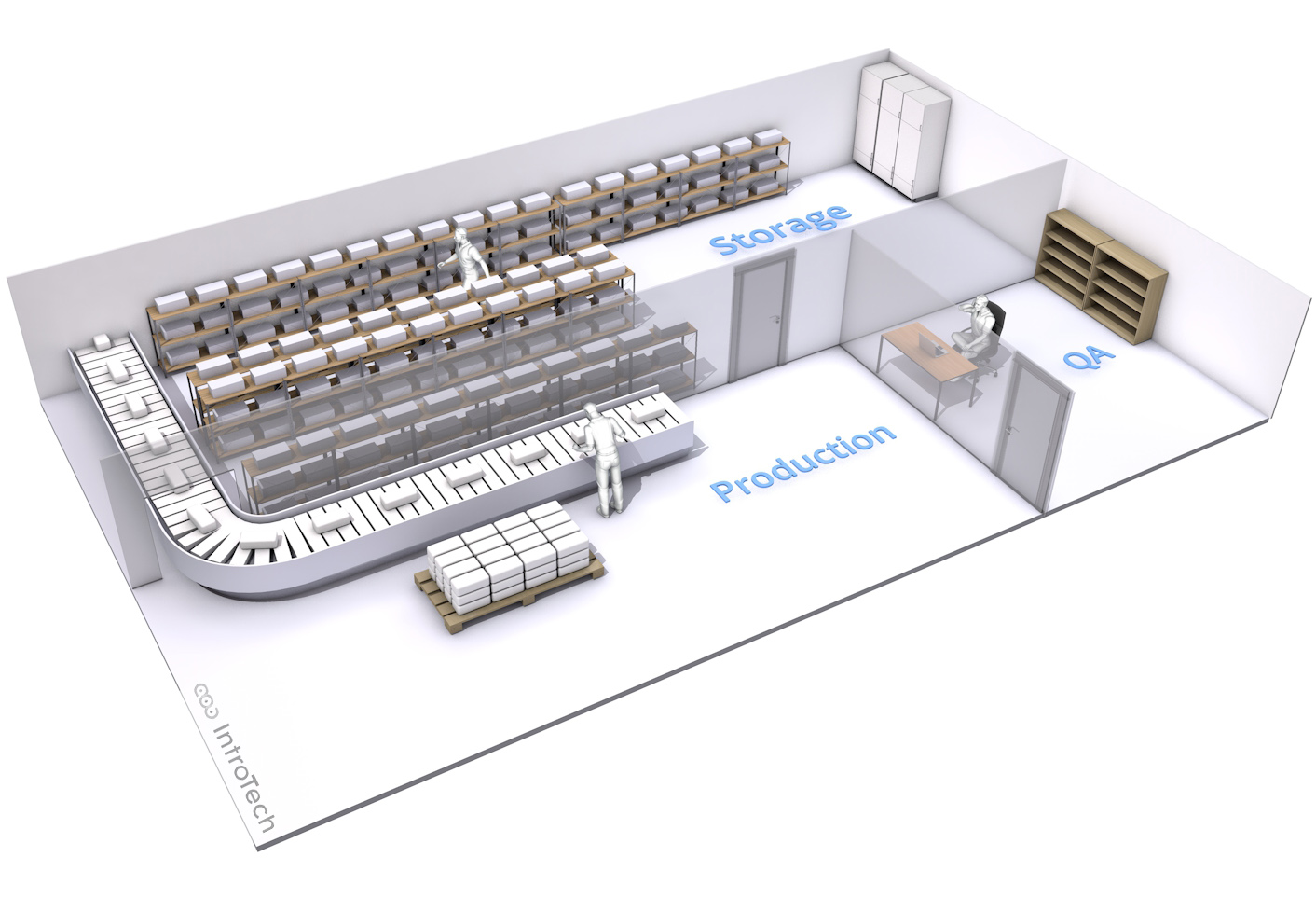

Central Monitoring Systems for facilities

A Central Monitoring System enables you to proof your regulatory compliance. GxP regulations prescribe that critical control point should be monitored 24/7.

Sensors are placed at critical control points which can record different kinds of data, such as temperature, humidity, numbers of particles (PPM), Co2 and pressure (Pa). Once the recorded data is transferred to the receiving base station, it is saved in the database and send to a cloud-platform. The gathered data is accessible via a secure web portal. If one of the critical control points exceeds their set limit, an alarm is send to one or multiple employees.